Shenzhen Fast-xawaaraha Turnkey PCB Assembly Elektroonik ah Guddiga Wareega Wax soo saarka oo leh Servicee Engineering Professional

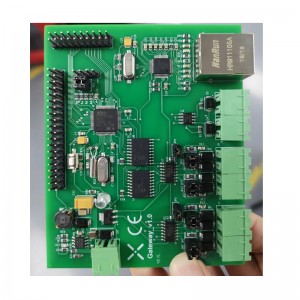

QAABKA Alaabada:

| Qalabka Saldhigga: | FR4-TG140 | Dhammaadka dusha sare: | HASL(LF) |

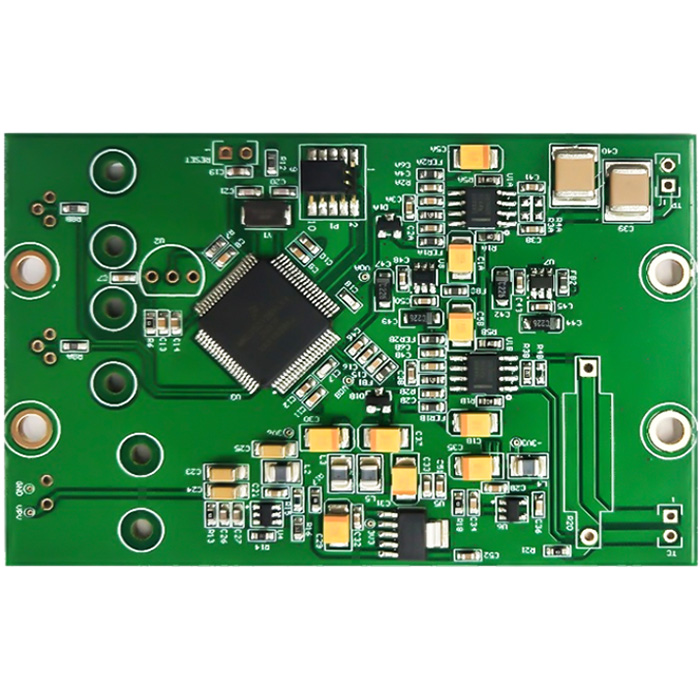

| Dhumucda PCB: | 1.6mm | Maaskarada Alxan: | Cagaaran |

| Cabbirka PCB: | 72*120mm | Shaashada xariirta: | Caddaan |

| Tirada lakabka: | 2/L | Cu Dhumucda | 35um (1oz) |

Sababta anaga:

1. Waxaan ku hawlanahay farsamaynta elektaroonigga ah in ka badan toban sano, oo khibrad qani ah u leh warshadaha.

2. Iyada oo leh shahaadada kaliya ee xirfadeed ee warshadaha- xawaaraha sare ee PCB naqshadeynta kartida gaarka ah.

3. Waxaa lagu dhejin karaa IC/BGA, masaafada cag ee ugu yar 0.25mm BGA masaafada ilaa 0.25mm.

4. Wax soo saarkeena dabacsan, waxqabadka qalabka sare, wuxuu qaban karaa ku dhawaad dhammaan mashaariicda alaabta.

Waxaan ku kalsoonahay in alaabtayadu ay u samayn doonaan kaabayaal meheraddaada oo ay horumariyaan qiyamkaaga ilaa tan ugu weyn.

| PCBWaxyaabaha salka: | FR4, Rogers, Aluminium,Copper-saldhig, PI, PET |

| Lakabka: | 1-32lakabka |

| PCBDhumucda: | 0.4-3.0mm |

| Dhumucda naxaasta: | 0.5-3OZ |

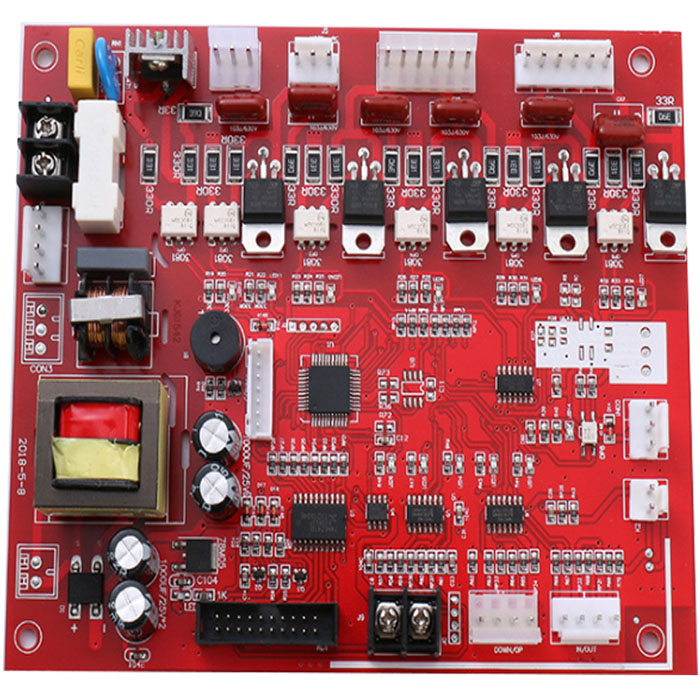

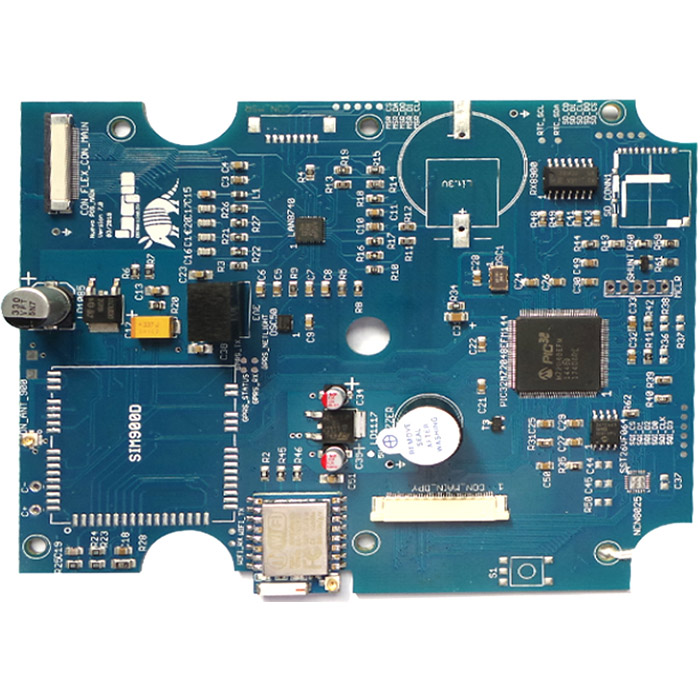

| Maaskarada alxanka: | cagaar, casaan, buluug, jaalle, madow, caddaan, guduudiwm |

| Min.ballaca xariiqda | 3mil |

| Min.booska khadka: | 3mil |

| Min.dhexroor dalool: | 0.25mm |

| Cabirka looxa ugu badan: | 600 x 1200mm |

| Dusha saredhame: | HALS/HALS macdanta rasaasta bilaashka ah/ daasad kiimiko ah/Dahab kiimiko ah/dahab la geliyo/ Immesion Silver Dahab/Osp/ Dahab Dahab ah, iwm |

| Shahaado | UL, ISO9001, ISO14001, ROHS, |

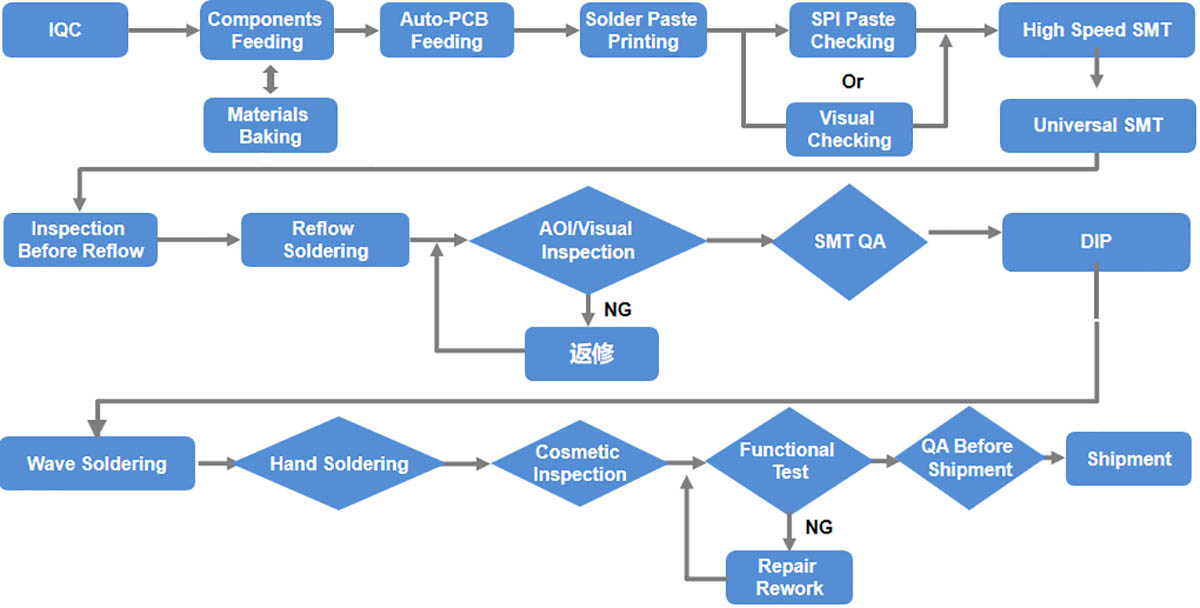

Geedi-socodka Golaha PCB:

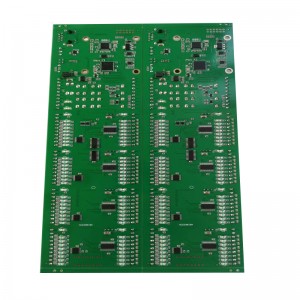

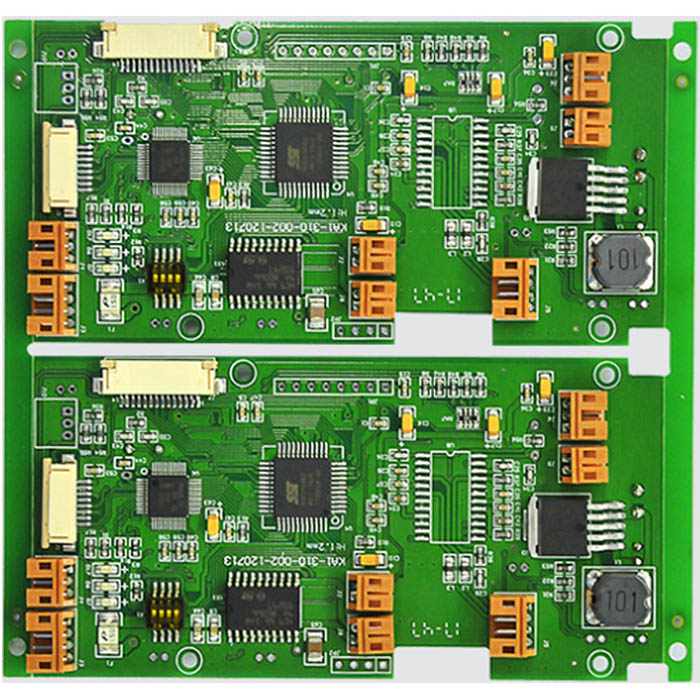

Alaabta ugu muhiimsan:

Sida aan u xakameyno tayada:

1. Dib u eegis habka:

1.1 Xaqiiji shuruudaha gaarka ah ee macaamilka iyo sifooyinka gaarka ah ee badeecada (kordhinta iyo iska caabinta heerkulka qaybaha qaabdhismeedka gaarka ah)

1.2 Xaqiiji in xogta wax soo saarka BOM iyo PCB ay yihiin kuwo casri ah, haddii ay jiraan shay la xaqiijinayo, iwm.

1.3 Qiimee in qaabka PCB (qaab dhismeedka guddiga wadajirka ah) uu yahay mid si ballaaran loo soo saari karo.

1.4 Qiimaynta wax soo saarka ee habka suufka gaarka ah ee guddiga PCB (dahab, OSP, daasadda buufinta, SMD, NSMD, iwm.).

1.5 Nakhshad habab kala duwan oo furitaan ah una dooro xaashida birta mesh kala duwan ee PCB-yada kala duwan.

1.6 Xaqiijinta iyo qiimeynta ku habboonaanta qaybaha gaarka ah iyo qaybaha kale ee gaarka ah ee leh suufka PCB.

2. Kormeerka soo socda (IQC)

Ujeedada kormeerka: si looga hortago habka wax soo saarka liidata oo ay ugu wacan tahay agabka liita iyo tayada aan u qalmin ee agabka dib loo cusboonaysiiyay ee khadka si looga hortago luminta gabowga.

3. Maaraynta kala soocida agabka:

Maamul agabka oo ku maamul agabka kala soocida.

4. Kormeerka koollada iibka ah ee SPI

Ujeedada kormeerka: horay u hel daabacaadda koollada alxanka ah ee cilladaysan si aad uga fogaato socodka nidaamka xiga.

5. Kormeerka AOI

Ujeedada kormeerka: si loo hubiyo in alaabada la soo saaray ay leeyihiin khaladaad, wax laga tagay, iyo agabyada xun ee ka baxaya nidaamka soo socda.

6. Kormeerka Qodobka Koowaad ee SMT

Ujeedada tijaabada: si loo xaqiijiyo saxnaanta habka meelaynta khadka wax soo saarka, si loo hubiyo in cabbirada qayb kasta oo RC ah ay ku jiraan heerka caadiga ah.

7. Kormeerka alaabta IPQC:

Ujeedada kormeerka: in la sameeyo kormeerid aan kala sooc lahayn ee dhammaan hababka wax soo saarka iyo haddii ay waafaqsan yihiin tilmaamaha shaqada.

8. Kormeer muuqaal ah

Ujeedada kormeerka: marka loo eego heerka IPC610D, baadh PCBA-ga dusha ku rakiban kaas oo loo iibiyay khaladaad, khaladaad, iyo xidhiidhada casriga ah.

9. Kormeerka alxanka X-Ray

Ujeedada kormeerka: si loo eego kala-goysyada alxanka ee asalka ah ee aan la arki karin indhaha qaawan si loo hubiyo isku halaynta kubad kasta oo alxanka BGA ah.

10. Kormeerka gacanta ee QC

Marka loo eego heerka IPC-610 ee kormeerka, looxyada la dhammeeyey waa la kormeeraa, 99.98% badeecadaha wanaagsanna waa la dammaanad qaaday in la raro.

11. Kormeerka QA ee shixnadaha

Si adag u baadh ka hor inta aan la rarin oo sawir koodka si aad u hubiso si aad uga hortagto in alaabta aan u qalmin in la raro.

FAQ:

1. Waa maxay awooddaada wax-soo-saar?

Awoodeenu waa celcelis ahaan 30,000 mitir oo laba jibbaaran bishii.

2. Kaliya waxaan haystaa muunada pcb, ma aha faylka pcb, ma ii soo saari kartaa?

Haa, waanu koobi karnaa faylka iyadoo lagu salaynayo muunadaada, faylkani wuxuu magacaabayaa gerber, ka dibna wax soo saarku waxa lagu siinayaa faylka gerber.

3. Waa imisa wakhtiga hogaaminta?

Waqtiga ledhku inta badan halkan waa wakhti, badiyaa 5-10 maalmood ee muunada PCB-ga, 10-15 maalmood ee wax soo saarka guud.Xaalado gaar ah, waxaanu sidoo kale kula talin karnaa macmiilka horudhac si uu uga fogaado wax kasta oo aan filayn ama khasaare dhinaca macaamiisha ah.

4. Waa maxay midabka maaskarada alxanka oo ma jiraan midabyo kale oo la heli karo?

Midabkayaga caadiga ah ee maaskarada alxanka waa cagaar.Waxaan sidoo kale ku siin karnaa maaskaro alxan oo casaan, buluug ama madow ah qadar dheeri ah.